Ensuring Quality Through Process Validation: Best Practices for Pharmaceutical Compliance

14 Oct, 2025

Introduction

Quality is something that we expect to be in everything we use, be it the food we eat or the clothes we wear. But if we talk about the medicines we consume and the pharmaceuticals, quality is something that needs to be there from the very beginning, and not just in the end product.

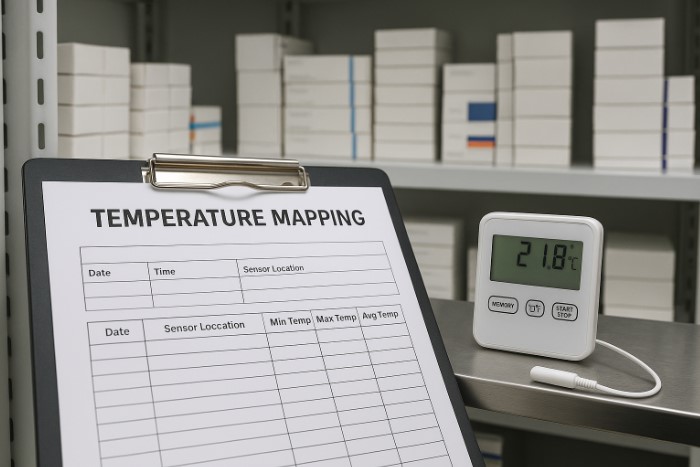

There needs to be high standards of safety and efficacy in every step and procedure of pharmaceutical manufacturing. To make sure all the standards of safety and quality are met, process validation comes in.

Pharmaceutical manufacturing goes through a lot of tests to ensure its quality. This process validation means proving that every step in the process delivers top quality.

Now, process validation has evolved into a journey. It has become a cycle of understanding and improving.

This whole process teaches you something new every day and helps you improve your systems so that you are coming up with the best quality product every single time.

Through this article, let’s understand how to ensure quality through process validation.

1. What Is Process Validation and Why Does It Matter

Process validation works as the proof that your manufacturing process works. It’s the scientific evidence that shows you can produce a product that meets all the specifications.

It connects development knowledge with commercial reliability and protects both patients and manufacturers.

If validation fails, there can be severe consequences.

2. Global Regulatory Framework

| Regulator | Key Focus | Highlights |

| FDA (U.S.) | 3-Stage Lifecycle Approach | Stage 1: DesignStage 2: Qualification (PPQ)Stage 3: Continued Process Verification (CPV) |

| EMA (EU) | Annex 15: Lifecycle + Risk Management | Validation Master Plan (VMP) required; no retrospective validation |

| WHO / ICH | Global Harmonization | Promotes Quality by Design (QbD) and continuous verification |

All major regulators focus on a lifecycle model. They are now moving away from “three batches and done” toward continuous evidence of control.

In one 2025 FDA warning, a company with unvalidated blending steps was ordered to do its entire process validation program again before distribution.

3. Understanding the Process Validation Lifecycle

Let’s understand the process validation life-cycle in a better way:

| Stage | Objective | Key Deliverables |

| Stage 1 – Process Design | Define and understand the process | CQAs, CPPs, risk analysis, control strategy |

| Stage 2 – Process Qualification (PPQ) | Demonstrate process consistency | IQ/OQ/PQ, PPQ batches, analytical results |

| Stage 3 – Continued Process Verification (CPV) | Maintain control during routine production | CPV reports, trend charts, CAPA actions |

Stage 1: Process Design

This is the initial stage of the whole process. Here, you understand your product and design the whole process of how it is going to turn out.

You start by identifying what defines quality. It is called Critical Quality Attributes (CQAs). You also identify the parameters that influence the quality – the Critical Process Parameters (CPPs).

Here, you use tools like Design of Experiments (DoE) and pilot-scale data to get the process right.

Stage 2: Process Qualification

Here, you validate your equipment and your operators. Then there is Process Performance Qualification (PPQ). In this, you have to run the process under predefined conditions, mainly three times successfully in a row.

Stage 3: Continued Process Verification

Then there is continuous verification. Here, the validation doesn’t stop once the PPQ is done. Instead, every single batch becomes part of an ongoing data stream.

By regularly monitoring potency, dissolution, or bioburden, you can figure out small shifts early, before they turn into problems.

Stage 3 keeps your process healthy. Its goal is to find small issues before they become big problems.

| Parameter | Control Limit | Current Mean | Status |

| Potency (%) | 95–105 | 100 ± 2 | Stable |

| Dissolution (%) | ≥ 80 in 30 min | 81 → 78 | Trend watch |

| Bioburden (CFU/mL) | ≤ 10 | 4 → 5 | Stable |

4. Best Practices for Sustainable Compliance

| Focus Area | Best Practice | Why It Matters |

| Validation Master Plan (VMP) | Define scope, ownership, and timelines | Keeps teams aligned and audit-ready |

| Risk-Based Focus | Prioritize high-impact process steps | Aligns with ICH Q9, reduces over-testing |

| Robust Protocols | Predefine limits, include worst-case runs | Avoids ambiguity during PPQ |

| Cleaning Validation | Challenge with the hardest-to-clean residues | Prevents cross-contamination events |

| Data Integrity | Real-time recording, secure audit trails | Builds regulator confidence |

| QA Oversight | QA approval at each lifecycle stage | Ensures independence and compliance |

In 1988, unvalidated cleaning of reused drums led to pesticide contamination in cholestyramine resin. It is a recall that reshaped cleaning validation standards worldwide.

5. Common Pitfalls and How to Avoid Them

| Pitfall | Impact | Prevention Strategy |

| Rushing PPQ without process understanding | Variability, failed batches | Perform full DoE and risk analysis first |

| Skipping CPV | Undetected drift | Establish trending and alert limits |

| Vague criteria | Data ambiguity | Use numeric, statistically justified limits |

| Weak change control | Loss of validated state | Review and re-validate post-changes |

| Poor documentation | Audit findings, compliance risk | Follow GDP, perform internal mock audits |

6. Documentation and Audit Readiness

When you complete all the steps together, a complete process validation package shows how everything was done from start to end. It’s evidence that your entire system is under control.

It includes:

- Validation Master Plan (VMP)

- Risk assessment and design data

- PPQ protocols, raw data, and reports

- CPV summaries and CAPA logs

- Change-control and re-validation records

Conclusion

Process validation is not just a regulatory requirement you have to follow. It is quite essential to keep the pharmaceutical quality good every day. It is a process that makes sure every pill and every vial is prepared and works the way it is supposed to.

All you have to do is bring together good science and ongoing verification. This will lead to a good quality process and end products. Good end products mean good value, and they will create trust with the customers.

When you follow the whole process correctly, you will create a system that delivers safe and effective medicines every single time.

At the end of the day, process validation turns compliance into confidence. It changes regulations from something you have to do into something that keeps your products and your reputation up to the mark.